Don’t do it, just don’t. Rent one, charter one, go and sail on other people’s boats – just whatever you do, don’t buy your own boat, you’ll regret it!

The two happiest days in a man’s life are when he buys his yacht and when he sells his yacht

a wise man

That’s what everyone said to me when I told them I was looking at buying my own boat … “A boat owner is only happy on 2 occasions, the day he bought his boat, and then the day he sells it,” they said.

Well, I listened and then completely ignored them and went ahead and bought my boat anyway. I ran the numbers, had a healthy contingency and wanted to experience the trials and tribulations. It can’t possibly be as bad as everyone was making out … can it?

I’d spent a good 2-3 years looking for the right boat, trying to find something which wasn’t a complete wreck but that I could still afford. Something that perhaps cosmetically wasn’t all there but physically was sound. After looking at what felt like 100 boats, I stumbled across Pamela C and instantly fell in love!

I arranged for the survey from a local company, one that seemed to have good online reviews (at least no terrible reviews) as I really didn’t know anyone, and the guy selling the boat just kept saying “Don’t bother getting a survey, they never spot any of the issues anyway”. Well, that was partly true .. but that’s a story for another day!

If it flies, floats or fornicates, it is cheaper to rent than to buy

Felix Dennis

The surveyor did find a few things that needed to be addressed, earth bonding wasn’t done properly, broken track, broken cheek blocks, gas certification was out of date, and a few other bits and pieces. These all helped in the negotiations, and I managed to get the vendor to drop his price by roughly 10% and, more importantly include several extra items he had originally said he would be removing/transferring to his new boat (Hydrovane wind vane, full AIS, windlass, etc.)

The vendor had been doing renovation work for a while, and there was new headlining, an electric toilet (pumping by hand is so very very very tiresome), and generally, things seemed to be in a reasonable order. The boat had been on the hard for almost 2 years, so it was impossible to look for signs of osmosis, but she seemed watertight and hadn’t let any water in during the recent torrential downpours, so I read that as a good sign.

There was some water in the bilges, but this was mainly traced back to a small leak through the centre cockpit around where the autohelm cables come through into the engine bay (some grease in the hole should sort that), and the stuffing box seemed to be leaking, again some grease in there and that should dry out fairly quickly. Worse case it just needed a bit of “rope” stuffing into the box and the nuts tightening.

So, I signed on the dotted line, transferred most of my life’s savings (in 3 instalments as I could only transfer £10k/day from my bank account annoyingly), and the boat was mine! I had 2 weeks to sort out the antifoul, address any other issues and get her in the water before the rental period on the hard came to an end. Yes, I could have extended this, but I didn’t buy a caravan; I bought a boat!

I arranged for one of the local (highly respected and recommended) rigging experts to look at the rigging, and he confirmed my fears that the rigging would need to be replaced.

The Rigging

The rigging was 10 years old, and whilst the surveyor indicated that it seemed to be ok, it was always going to be down to the insurance company to accept 10-year-old rigging on their risk. As it was, the insurance company didn’t seem to care, but I wanted an expert to take a look, so with the boat still on the hard, I got Andy Gordon of AD Gordon Rigging to have a look. He spotted a number of issues, including a fault with the gooseneck that the surveyor should have spotted, and I decided that it was best to replace the rigging now rather than in the next couple of years as I had originally planned.

Quotes came in, and they were between £5k and £7k. Andy Gordon was actually towards the lower end of the estimates, so coupled with the generally positive recommendations from everyone in the local area (and the fact at least one of the big boat companies I went to called Andy for a quote as they always use him for their rigging work), I instructed AD Gordon Rigging Ltd to replace both the standing rigging and also the running rigging.

To do this, the boat would have to go into the water as they’re not allowed to work on / climb the mast whilst the boat is in storage at the National Sailing Academy. So a lift was booked, and the boat went into the water Thursday 8th July 2021. I had to arrange temporary berthing for her at Portland Marina (where I am trying to get an annual berth, but they’re running a waiting list currently) and of course, that means paying visitor rates, not berth holder rates – £1,000 per month roughly – something I hadn’t budgeted for.

I had a contingency budget of up to £6k/year for berthing if I chose to keep her in marinas, but my main plan was life on the hook and life in the sun! (plus, I hadn’t expected a number of the additional costs that have been racking up).

I speak to Andy Gordon and he tells me that there is a crane lift at Clark’s yard Friday morning and that the 2-week window should be enough time, so long as there are no delays in getting the parts from suppliers. So off we go.

The mast comes off on July 9th at 9 am and is due back on before July 22nd. Happy Days!

The Big Clean

While the boat is on the water, I’m busy cleaning and tidying and removing 45 years worth of dust, pubic hair and grime – I don’t think this boat has ever really been cleaned. I enrol friends and my girlfriend to help; we bring the Karcher jetwash down and blast the decks and the teak woodwork. She’s looking better now, so much cleaner! The paint is flaking, but that’s ok; that’s the next job – sand the decks and re-paint. (why do this on the water where it is more expensive? Well, I didn’t want to be responsible for friends falling down ladders or off the deck (3m above ground currently) and breaking bones, or worse)

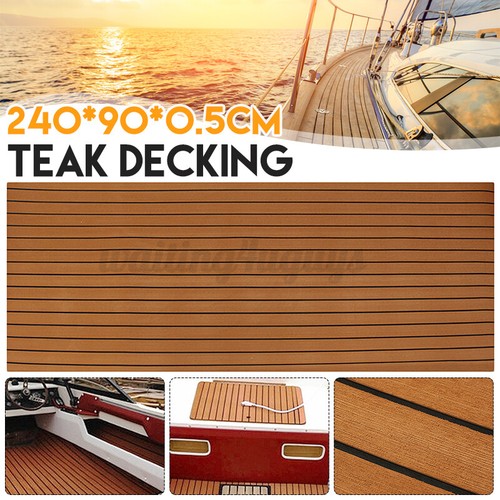

Then I meet one of the locals (Dan) who knows the boat and a little of her history as he used to be moored near her in the bay. Dan suggests using EVA Foam instead of painting the deck .. cheaper, looks nicer and easier on the bare feet too! … So off I go to eBay to find and buy some. That turned out to be easier said than done, with one seller cancelling the order as he had problems with his supplier, and the second attempt going missing inside Yodel for nearly a week .. but the decking finally arrived, just as all my volunteers had headed home, so I’m left sanding, measuring, cutting and sticking on my own – I’ll let you know how that pans out next week!

Going around the safety equipment on the boat, it is evident that it needs replacing/servicing/purchasing. The danbuoy has definitely seen better days, there are no throwable flotation devices, there were 2 lifejackets (which I believe are from the Titanic), the liferaft needs a service (£385?), the EPIRB needs a service (£250? They’re only £400 new!) and I need to buy lifejackets (8 of which cost me £2,100 plus another £500 for 2 x MOB alarms).

I think Ian at Pirates Cave Chandlery in Rochester must have thought all his Christmases had come at once when I walked in and 5 minutes later had spent over £2,500 on 8 lifejackets and a load of other bits.

The Water Tanks

When I spoke to the vendor, he told me that he’d taken the water tanks out to replace the wood they were sitting on as it had rotted. He agreed to put the tanks back in before the sale, which he did, he just didn’t actually connect them!

As a result, I now have to lift the floor and work out the pipework and routing for the freshwater storage system. Having done so, I’m not convinced that I want to keep the bladders (tanks) for long, although they are working currently, and having pumped a large amount of Aqua Sol through them I’m relatively convinced that they’re sterile and the water won’t kill me. I still think that longer-term they need replacing, but that’s yet more time and money!

The Mast (continued)

July 22nd comes and goes. There’s a problem with the mast too. It has some structural issues due to aftermarket modifications and needs braces to restore structural integrity (currently it has perforations all the way around), custom-made braces, which will add a week or two and £500. The spreaders are corroded too, so they’re going to need rebuilding – that’s another £300. The winches are in serious need of repair and service, so that’s another £500 too. We’re now rapidly approaching and passing the £7k figure for rigging repairs, and we haven’t yet got to the running rigging and blocks that are going to need to be replaced.

August 5th, and still no mast. We have, however been busy plugging away at the internals. There were a number of issues with the 12-volt electric system, not least of which was an electrical short, which could have caused the entire boat to burst into flames, thankfully that was located. The earth bonding had been cut out in places and not restored – very strange. Without adequate bonding, the boat will suffer from galvanic corrosion, and the keel, rudder and propellor could all corrode and fall off, not to mention the through fixings could all corrode and crumble, leaving the boat like Swiss Cheese and sinking. That had to be addressed, and the shore power connector was heavily pyrolysed and ready to catch fire due to either a leak or just poor installation by the previous owner).

The Shower

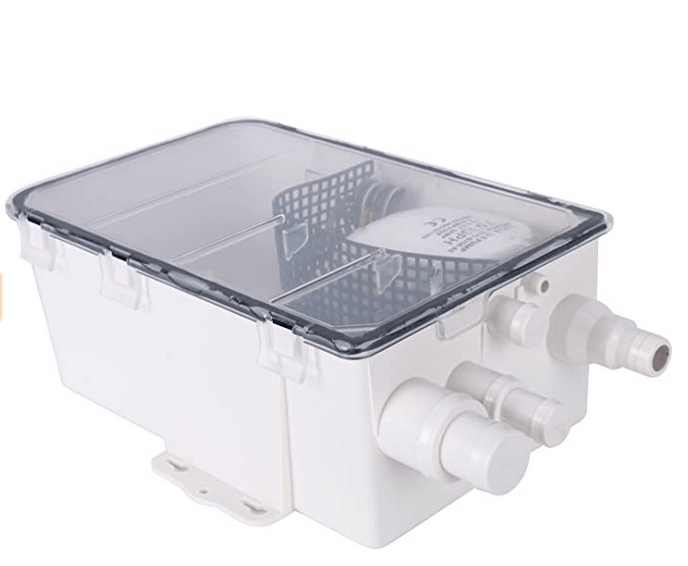

Another issue identified by the surveyor was that the shower was draining into the bilges. This is unhygienic and suboptimal. It turns out that this is actually a relatively easy fix though, there should be a shower sump that catches the pubic hair/etc, in a trap and pumps the dirty water out of the boat through one of the skin fixings. £35 later from Amazon and a new 750 GPH shower sump has been acquired, and we now just need to work out whether any of the myriad of cut wires under the floor is actually meant to power the sump or if we need to run a new 12v power feed to the sump – a job for next week.

Portland Marina has been very helpful and has now extended berthing until August 26th, which takes us to the end of Portland Week – when there will be fun and games “on, above and below the water” apparently! Hopefully, by then, I’ll have a mast, functioning sails and be able to at least sail around the local area.

The Windlass

The windlass was left on the boat by the previous owner but in a locker. It had been taken off to be serviced, and while it was away, they had apparently lost the motor, and it needed a whole new motor to be installed at a cost of £900 that was paid for by the company the windlass was sent to for the service. The plus side of this is that whilst the old windlass was “up only”, this new one is reversing and can go down as well as up! (To release the anchor you had to undo the clutch and bail the chain out by hand).

Fitting the windlass was a job and a half. The old solenoid had corroded away (and was a 2 pole, 1 way, solenoid). A new solenoid was sourced (£65) and after some experimentation, I was able to wire it up and get the windlass working! It was at this stage that I realised the old anchor chain was probably not going to hold in any serious blow, and the Danforth anchor didn’t really fit on the bow roller (plus it was bent and battered and again probably wouldn’t provide great holding in windy conditions).

After some research and investigation, I settled on a new Lewmar Delta anchor. When I tried to order this, however, I was advised that they weren’t readily available, that there were a number of issues with them and that I would be much better off with a Mantus M2 anchor instead. I looked at the Mantus, saw some reasonably positive reviews online, and decided the price (£513) was right and the spec too. Whilst talking to Ben over at Pro Marine Store, he managed to upsell me on the Ultra Swivel – guaranteed to ensure the anchor is the right way up every time, so no issues getting it onto the bow roller (unlike the Danforth, which I actually had to lasso and manhandle onto the deck when I brought it up – not something I want to be doing in a swell!). I also ordered 60m of new 10mm G40 anchor chain, and as a result, was some £1,500 poorer in a matter of minutes!

The new anchor, chain and swivel are absolutely awesome however, and I am very very happy with the purchase!

The Electrics

We also tidied the electrics in the engine bay. We replaced the archaic Merlin trickle charger with a shiny new Victron Energy IP43 Smart Charger (£500) .. a really cute bit of kit with Bluetooth support so you can monitor the battery status on your phone from anywhere on the boat. More on this in another post.

In the engine bay, there were cut/bare/exposed wires everywhere. It was a mess! It needed an audit, and that’s where Daz of Marine Tech came in. Daz is an amazing guy and has been an inspiration and guide on several things, helping me get to grips with the electrics and other aspects of the boat. I can highly recommend his services! We soon tidied up the loose wires, random nuts and bits of wire that went nowhere. Daz drop tested each of the batteries and (to my surprise), gave them a clean bill of health. One less immediate expense (although longer-term, they do need to be replaced with Lithium for longevity and to support the inverter / etc that I want to install).

Still to do

The major expenses still to be incurred include solar panels, an inverter and a water maker. Combined, these will cost about £8,000, oh and of course the mast still needs to go back on – so there could be yet more costs there which I’m not expecting! 🙁

In addition, upgrading the chart plotter and instruments will likely cost another £10,000 to bring them up to state of the art. I really like the B&G Zeus3S system, but that’s outside my price range currently, unless B&G want to sponsor me 🙂

I also need to buy a tender and outboard motor if I’m going to live on the hook, as I’ll need transport to get from the boat and into the marinas/beach/etc. That’s potentially another £3k-£5k new (or £1500 second hand)

Part 2

Part 2 coming next week when I go into more detail about the water systems, the mast, decking and other joys of buying a 1977 yacht that hasn’t been in the water for almost 2 years!

Congratulations on your purchase and well done on the journey so far. I read with interest your challenges and solutions. You haven’t compromised on anything as yet which has resulted in all round improvements and long term reliability (hopefully). Up and down on the windlass a real result! Looking forward to the next instalment. Fingers crossed it’s not too painful on the wallet. As a long time sailor, always available for a chat. I’d like to think I have picked up some useful knowledge over the last 30+ years.